Product Application

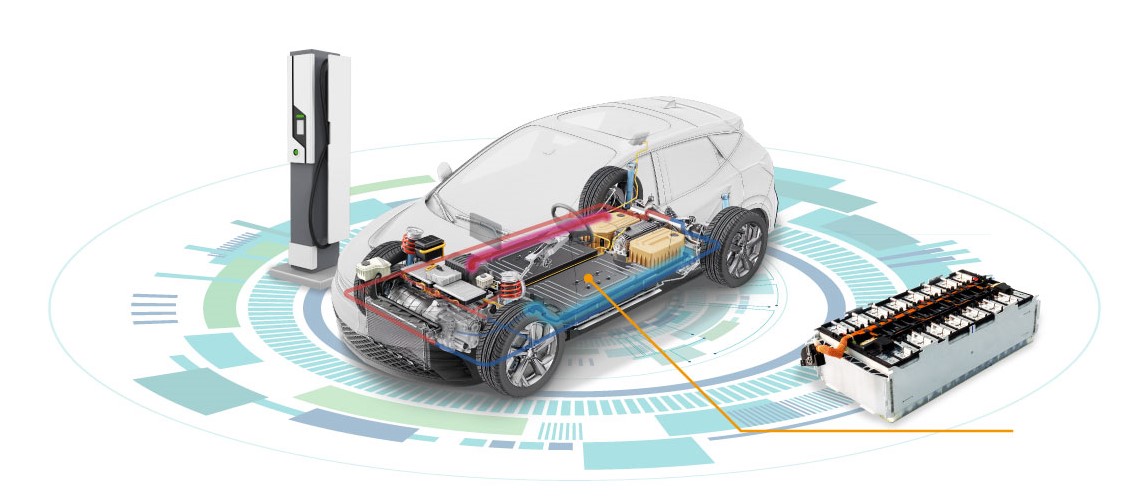

Battery pack, the power source of EV, is the major part of electric vehicle (EV), and its safety and endurance are the major technologies of manufacturers. Battery pack relies on battery management system (BMS) for its maximum performance and lifespan. BMS manages charging, discharging, and safety of battery pack, and it also enhances overall performance of EV.

Battery modules are part of BMS, and they are formed by several battery cells. Condition of BMS is shown by temperature change of battery cells. When battery cells are under normal operation, their temperatures are close. However, if temperatures of battery cells are different, they are under abnormal condition. A battery module usually has 1 to 4 temperature detection points to monitor its temperature, and the collected temperature data is sent to BMS. NTC thermistor is an ideal component for temperature detection because of its quick response.

NTC thermistor sense temperature directly and indirectly for its best temperature detection. For direct temperature detection, the component is installed either in battery for temperature detection of battery module or busbar for busbar temperature detection. For indirect temperature detection, NTC thermistor is installed on major cable connector or cover board. For either direct or indirect temperature detections, THINKING offers NTC thermistors with different materials and structures to meet those needs.

Simple structure is the feature of NTSE series, epoxy coating type NTC temperature sensor. The component is with high commonality and its cable length and structure can be customized for customer’s mechanism. For its use in busbar, the picture below indicates NTSE product is installed in busbar for busbar temperature detection, and its structure is customizable.

TSM series is SMD NTC thermistor from THINKING, and its small size and light weight meet needs of limited installation space. High reliability of the product is from its glass coating, and technology of THINKING offers it quick response time. In addition, TSM series is suitable for FPC automatic production because of its SMD structure, and customers increase their manufacturing efficiencies via this adoption.

NTSA series is screw-on type NTC temperature sensor, and it can be fastened with simple screw-on installation. Voltage sensing line for circuit design is also available for this product. For customer’s needs, various terminals (including M3, M4, and M5) are available, and cable length of the product can be adjusted to mechanism.

NTSB series, plastic encapsulated type NTC temperature sensor, is reliable and moisture resistant because of its structure and coating material. When the component assembles with busbar, aluminum thermal conductive sheet of busbar conducts busbar temperature to it, and the method lowers temperature detection error and shortens response time.

NTSB series is recommended for automatic production because its assembly with busbar is easy and fast, and this method maintains stable quality and lowers human error. Furthermore, aluminum soldering plate of the product make it suitable for aluminum wire bonding manufacturing process, back end manufacturing process of battery module. THINKING not only offers NTSB series but also provides assembled product of NTC temperature sensor with copper/aluminum busbar to better serve its customers.

NTSH series is a temperature sensor with two NTC thermistors, and its NTC thermistors are moisture resistant in that its sensing top is glass coated. Furthermore, structure of the sensor enables customer’s easy installation or replacement. Flat design of the sensor is suitable for temperature detection of cover plates of battery modules. Furthermore, Technology from THINKING offers high pressing and load-carrying capacity of the body, and makes it suitable for harsh environment.

Automobile manufacturers focus on development and thermal stability of BMS because BMS increases EV safety. Temperature detection plays an important role for BMS operation, and BMS manufacturers require reliable and precise NTC thermistor to maintain the best quality of their product. With over 40 years experience in temperature sensor industry, THINKING provides various NTC thermistor to satisfy customer’s needs, and its automatic production of temperature sensor offers stable quality of its products.