Product Application

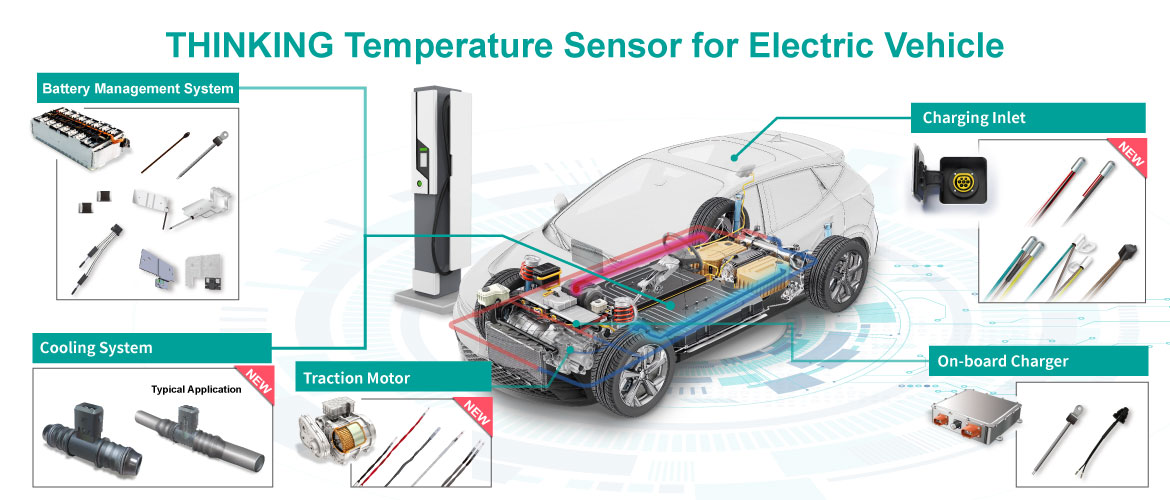

Thermal management is crucial in electric vehicles, and temperature sensors play a critical role in optimal thermal management. As the expert of NTC temperature sensing, THINKING has developed and customized various temperature sensors to meet specific electric vehicle requirements. Our automotive temperature sensors measure the temperature of critical components and sub-systems, including the battery pack, motor, on-board charger, cooling system, and charging system.

The right temperature sensor can help make e-mobility safer, reliable, and efficient. THINKING NTC temperature sensors for EV battery management, liquid cooling system, motor, and charging inlet can help EV advance its thermal management.

for liquid cooling system

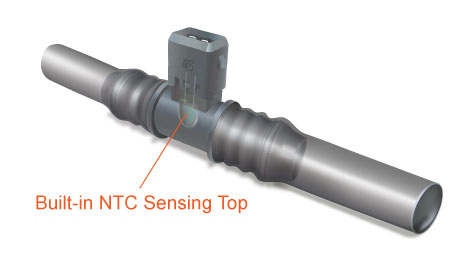

The Inline Flow-Through Fluid Temperature Sensor for liquid cooling system consists of a hydrolysis-resistant plastic tube and a THINKING NTC thermistor specifically developed for application in harsh environments. The NTC temperature sensor is designed to connect with inlet or outlet hoses and measures the temperature of the fluid that flows through its sensing top.

The Inline Flow-Through Temperature Sensor features high measurement accuracy. The application specification requires that the difference in temperature measured by the temperature sensor and the fluid being detected is within ±1°C, which made design of the temperature sensor challenging because the NTC element is insulated in the plastic tube and measures the fluid temperature indirectly. Our engineering team conducted several tests and optimized the NTC temperature sensor design to meet the requirement.

One of the tests verified whether the Inline Flow-Through Temperature Sensor could measure the coolant temperature precisely in a simulated low-temperature environment. The NTC temperature sensors were connected to hoses and placed at a still ambient temperature of -30℃. Meanwhile, the thermocouples were fixed near the sensing top of the temperature sensor for direct contact with the fluid. Next, a 20℃ coolant fluid flowed into the hoses, and the differences in temperature detected by the NTC temperature sensors and the thermocouples were recorded for comparison. The test results below show the differences in temperature between the NTC temperature sensors and the thermocouples ranging from -0.1° to -0.3°C, indicating that the performance of the Inline Flow-Through Temperature Sensor far exceeds the specified requirement, and it can effectively monitor the coolant temperature in the thermal management system.

.jpg)

THINKING offers two sensor configurations for connecting a rigid polymer hose or an elastomeric hose. The temperature sensor with hose barb fitting grips the inside of a rigid polymer hose and provides a secured connection, as demonstrated in the installation example above. The temperature sensor for elastomeric hose, on the other hand, is without barb fitting and requires an additional clamp to increase the holding power for securing the connection. The sensor configurations not only reduce the installation spaces required but also avoid the risk of fluid leakage when compared to a threaded temperature sensor that needs a mounting hole on the hose. In addition, a connector base is integrated with the sensor tube to provide flexibility in replacing compatible connector.

Battery pack, the power source of EV, is the major part of electric vehicle (EV), and its safety and endurance are the major technologies of manufacturers. Battery pack relies on battery management system (BMS) for its maximum performance and lifespan. BMS manages charging, discharging, and safety of battery pack, and it also enhances overall performance of EV.

Battery modules are part of BMS, and they are formed by several battery cells. A battery module usually has 1 to 4 temperature detection points to monitor its temperature, and the collected temperature data is sent to BMS. NTC thermistor is an ideal component for temperature detection because of its quick response.

NTC thermistor sense temperature directly and indirectly for its best temperature detection. For direct temperature detection, the component is installed either in battery for temperature detection of battery module or busbar for busbar temperature detection. For indirect temperature detection, NTC thermistor is installed on major cable connector or cover board. For either direct or indirect temperature detections, THINKING offers NTC thermistors with different materials and structures to meet those needs.

● Epoxy Coating Type NTC Thermistor: Simple structure is the feature of NTSE series, epoxy coating type NTC temperature sensor. The component is with high commonality and its cable length and structure can be customized for customer’s mechanism. For its use in busbar, the picture below indicates NTSE product is installed in busbar for busbar temperature detection, and its structure is customizable.

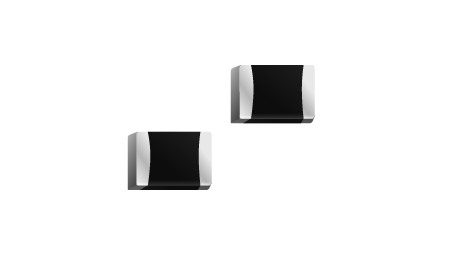

- ● SMD NTC thermistor: TSM series is SMD NTC thermistor from THINKING, and its small size and light weight meet needs of limited installation space. High reliability of the product is from its glass coating, and technology of THINKING offers it quick response time. In addition, TSM series is suitable for FPC automatic production because of its SMD structure, and customers increase their manufacturing efficiencies via this adoption.

- ● Screw-on type NTC temperature sensor: NTSA series is with ring terminal for secure and simple screw-on installation. Voltage sensing line for circuit design is also available for this product. For customer’s needs, various terminals (including M3, M4, and M5) are available, and cable length of the product can be adjusted to mechanism.

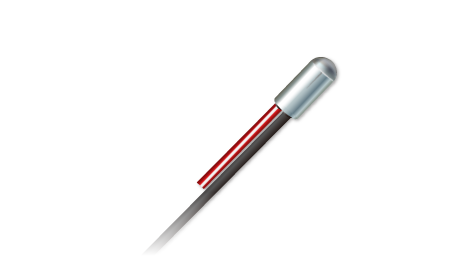

In an electric vehicle, the traction motor runs efficiently in the temperature range of about 90 to 100℃ and overheating may decrease its efficiency. In addition, overheating caused by overload or stall conditions in a traction motor will damage the windings or motor insulation. Therefore, monitoring the temperature of the motor, especially that of the stator winding is critical for preventing windings from overheating and keeping highest possible motor operation efficiency.

Features of stator winding temperature sensor

● Wide operating temperature range: -40ºC to +200ºC

● Utilizing THINKING high-temperature NTC thermistor, which offers excellent accuracy, stability, and reliability

● Sensing top covered by dual-layered heat shrink provides excellent resistance to mechanical shock, moisture, and corrosion

● The sealing is tested for air tightness

● Alternative length of lead wires, terminals, connectors, and electrical characteristics are available

for Charging Inlet

THINKING specifically developed a series of accurate temperature sensors for temperature detection of electric vehicle charging inlet. During the charge cycle, high current running through the connectors over a long period of time may generate high heat and can be a potential safety hazard to components and users. Therefore, monitoring the temperature of connectors is critical to increase charging safety.

- The temperature sensors are designed to resist moisture and corrosions in case that charging interfaces exposed in highly humid or dusty environment.

- Key Features of the Sensors

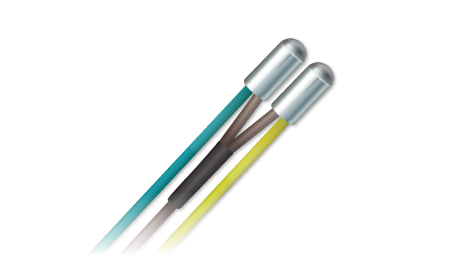

- ● Metal case type: The standard metal sensing top allows flexible installation

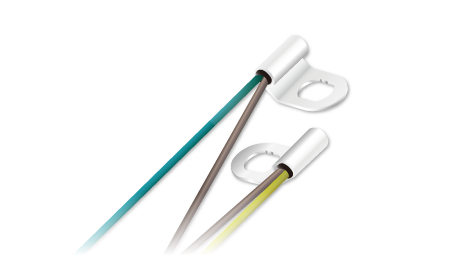

- ● Plastic case type: The plastic type is specifically designed for seamless contact between connector and sensor. The sensor touches the connector directly so that the temperature detected is more precise.

- ● Multiple sensor structure: For multiple points temperature detection, there are two multiple sensor structure options available. One is metal sensing tops with high dielectric strength, and the other is with ring terminals for simple and robust screw-on installation.

Want a standard or a custom sensor? We have the sensor for you.

Most temperature sensor types can be delivered in various shapes and with a wide choice of casing materials, cable lengths, terminals, connectors, and mounting features to meet different application needs. Alternative resistance ratings, resistances tolerances, R/T characteristics, are available on request.

THINKING has designed NTC temperature sensors with different geometry for specific application requirements. Include temperature sensor design in your product concept phase will allow our sensor design engineers to provide our thermal design experience and optimize the temperature sensor integration.

Ready to get started? Tell us about your project and the deisgn considerations of temperature sensors.