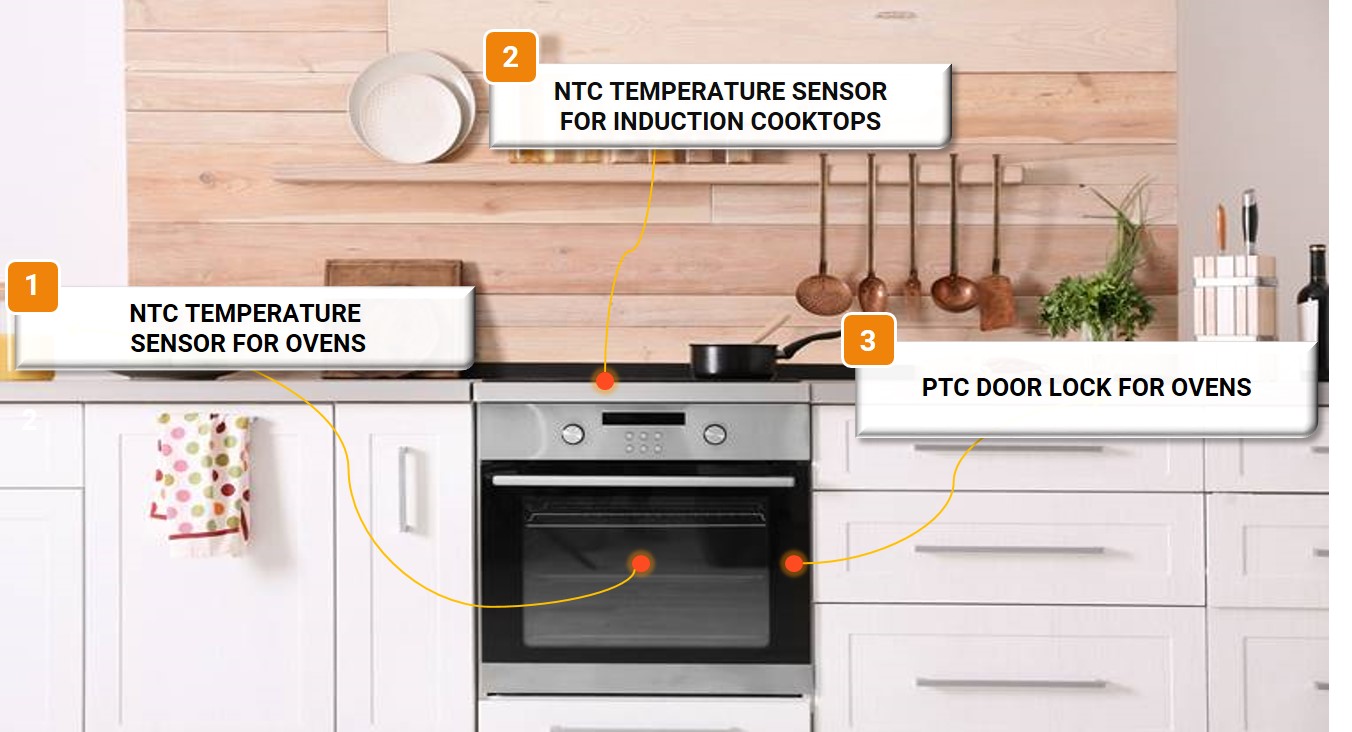

Product Application

Ovens and cooktops are essential in kitchen. The design of induction range, which consists of an induction cooktop and a stove, is becoming popular for its sleek look and consistent element temperature settings. THINKING offers a variety of reliable high temperature sensors to help electric ovens and induction cooktops achieve accurate temperature sensing and control.

for Ovens

Modern electric ovens are migrating from traditional heating method to multifunctional combination ovens. Convection oven delivers fast and even cooking results, while combination oven offers a wide range of cooking methods and temperature settings. To detect air temperature and controls the heating procedure, a temperature sensor is usually placed in the oven cavity and is required to withstand the temperatures of 200°C. THINKING’s NTC temperature sensor, potted in a stainless steel case with heat resistant lead wire, can measure a temperature of up to 300°C.

for Induction Cooktops

Induction cooktop is getting more popular because they heat up consistently, respond fast to change, and control temperature precisely.

For induction range applications, THINKING’s NTC temperature sensors are available with an aluminum cap or a ceramic cap. Aluminum cap enables the sensor to respond fast to thermal change, while ceramic one provides great insulation and resistance to both high voltage and high temperature so the sensor is merely affected by electromagnetic energy. The flat surface of sensing top is closely coupled to the heating surface for accurate temperature detection. In addition, the NTC temperature sensor can be constructed with silicone rubber holder to fit better to the induction burner hotplates.

For portable induction cooktops, a glass coated NTC thermistor assembled with silicone seat or heat shrink tubes is in direct contact with the heating surface and responds fast to thermal fluctuation.

During pyrolytic self-cleaning cycle, the oven becomes very hot and the door is required to stay locked to ensure user safety. An innovative door interlock design incorporates PTC stone (PTC heating element) to enable the locking mechanism. During pyrolysis, the PTC stone in the door interlock assembly is electrified to heat up to bend the bimetallic strip, which then activates other mechanical parts to keep the door locked. When the pyrolytic cleaning cycle is completed, the door will continue to stay locked for a period of time until the oven temperature has dropped to a safe temperature.

‧ In addition to temperature sensors, THINKING offers a broad line of circuit protection components to protect the latest appliances. Click here to see circuit protection recommendations for home appliances.

‧ Most temperature sensor types can be delivered in various shapes and with a wide choice of casing materials, cable lengths, connectors, terminals and mounting features to meet different application needs. Alternative resistances tolerances, R/T characteristics, resistance ratings, and UL recoginized models are available on request. Please contact us to learn more about temperature sensors.